I-Crystal-plated Crystal Cylinder-igolide yokuTyala kunye noKutyathwa kobhedu

Ingcaciso yeMveliso

Ubungakanani obuncinci belaser crystal lasers bunokufumana amandla aphezulu kunye nomgangatho olungileyo we-beam ngokusebenzisa le ndlela yokuwelda, kodwa kubukhulu obukhulu (≥100mm2) iikristale ze-laser ze-slab, le ndlela yokuwelda iqhelekile kwi-voids enkulu (≥ 1mm2), indawo enkulu ye-solder ebonakalayo, kunye nokuhanjiswa kwe-solder ye-solder layer ayilingani. Oku kungenxa yokuba ikristale ye-laser slab ifudunyezwa kwindawo yokucoca, inqanaba lokuqhuba ubushushu liyacotha, kwaye inkqubo yokufudumeza kunye nokupholisa iyacotha, ikhokelela ekufudunyezweni okungalinganiyo kwekristale ye-laser, kwaye kulula ukubangela ukuba inxalenye yesolder inyibilike kuqala, inxalenye emva kokunyibilika, kunye nenxalenye yesolder ukuba inyibilike kuqala. Ukuqinisa, enye inxalenye yesenzeko sasemva kokuqinisa. Ngoko ke, ngexesha lokufudumala kwekristal ye-slab ye-laser, inxalenye ye-solder enyibilikayo kuqala igqibezela i-welding kwaye ihamba, ijikeleze inxalenye enganyibilikiyo, ekulula ukwenza iingxaki ezifana ne-voids, i-solder ebonakalayo kunye nokusabalalisa okungalinganiyo kwe-solder. Kwinkqubo yokupholisa phantsi, umda we-slab laser crystal uhlala upholile kuqala. Ngoko ke, i-solder emphethweni iqinisa kuqala, kwaye emva koko ipholisa inxalenye ephakathi eqinisiweyo. Isigaba solwelo sijikela kwisigaba esiqinileyo kwaye sithande ukucutha umthamo, oqhelene ne-voids kunye ne-solder ebonakalayo.

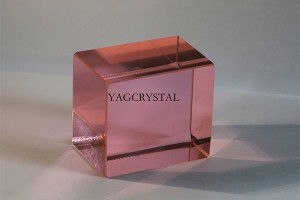

Inkampani yethu inokubonelela ngegolide kunye neenkonzo zobhedu. umlekwe wegolide, walukwa ngeentsimbi ezilucwe, nesalekwe ngegolide. Umsebenzi kukuba ikristale inokudityaniswa ngokuqinileyo kwisitya sobushushu, kwaye inokuphelisa ubushushu ngaloo ndlela iphucula umgangatho weplanga.